Weld Wheels RT-S Application Guide - CTS-V / Camaro / Corvette / GM / Ford / Dodge - CURRENT AS OF 2/2/2024

APPLICATION GUIDES

- RT-S Buick Wheels Application Guides

- RT-S Cadillac CTS-V Wheels Application Guide

- RT-S Chevy Car Wheels Application Guide

- RT-S Dodge and Chrysler Wheels Application Guide

- RT-S Drag Truck and SUV Wheels Application Guide

- RT-S Ford Car Wheels Applications

- RT-S Ford 4-lug Wheels Application Guide

- RT-S Nissan Car Wheels Application Guide

- RT-S Oldsmobile Wheels Application Guides

- RT-S Pontiac Wheels Application Guides

- RT-S Toyota Supra & Honda Wheels Applications Guide

- Race Frontrunner Application Guide - All Makes/Models

- DFS Wheels Application Guide - All Makes/Models

In their most basic form, wheels are pretty simple, but performance racing wheels are a complex set of calculations and engineering principles that are more complex. Weld engineers have at their disposal more design, engineering and testing tools than any other racing wheel manufacturer. Using programs such as Finite Element Analysis (FEA) and engineering concepts such as Rotational Moment of Inertia (RMOI), WELD engineers have designed and engineered wheels from 10” to 26” in diameter for virtually every type of application, including the more than 30,000 part numbers listed on our website. Located in Kansas City, USA, WELD is as an engineering performance driven company that lives the racing application through leading edge designs and real world results. WELD is not trying to reinvent the wheel, just perfect it. For nearly five decades, the WELD Wheels brand has been known throughout the automotive aftermarket as the premier aluminum performance wheel manufacturer in all forms of motorsports – and we intend to keep it that way. Please use our Tech Pages as your technical resource for all things wheel-related. The links below contain information on how to measure wheels, how to measure wheels for your vehicle, how to measure offset and backspace, and which WELD wheels will fit your vehicle. If you have a question and can’t find an answer in our FAQ’s or wheel tech bulletins, feel free to email info@weldracing.com or call one of our Technical Sales Representatives.

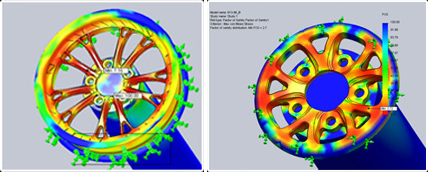

FEA: Finite Element Analysis – the collision between art and science. Wheel construction is at the intersection of art and science. The scientific element appeals to that little engineer inside most racers, and the art element appeals to well, that other side – we like our wheels to look like performance wheels. Finite Element Analysis, or FEA, is a tool that WELD engineers use to navigate that intersection between art and science, and is the type of stuff some of us would have paid more attention in high school science if we would have known how it applied to cars and racing. Listen to our engineers talk about FEA, and you come to understand that a wheel can be too strong in some areas, and removing mass in that area spreads the load more evenly across the surface, which makes the product as a whole stronger. The goal is to make the wheel as strong as necessary for the intended application but at the lightest possible weight, and with a factor of safety in place. The answer to making it lighter – and stronger – is not always obvious. In other words, drilling more holes to lighten a racing component is neither science nor art.

Weld racing wheels incorporate a lot of 3 dimensional contours that other wheel manufacturers may not. These contours appeal to the artist, but also serve an important role in spreading the load, or in FEA terms, minimizing the “hot spot”. Once the wheel design is loaded and constrained in the computer, the engineer applies various loads and lateral forces which, from our 49 years of racing experience, reflect the real word racing environment, and the result is a color coded digital wheel as shown above. Sometimes the results surprise us, other times it tells us what we expect. What we do know is that every time we test a wheel or rim, we learn something, and what we learn on an oval track wheel may also apply to a drag wheel or any of our other forged performance wheels and rims. FEA can give us a optimal wheel strength answer a majority of the time, but every new wheel and rim design we make is also built and physically tested in our in-house destructive testing lab. There are multiple tests we run, but all of them are designed to try to break the wheels and rims and find out how much pressure it takes. Designing a forged performance wheel that is best-in-class in all critical attributes; weight, strength, RMOI, concentricity, yet still good-looking – requires an artful eye, experience, software and everything in between. Sounds complicated? It is, and that is why decades, 49 years to be exact, of engineering experience make WELD the leading manufacture of forged performance wheels and rims.